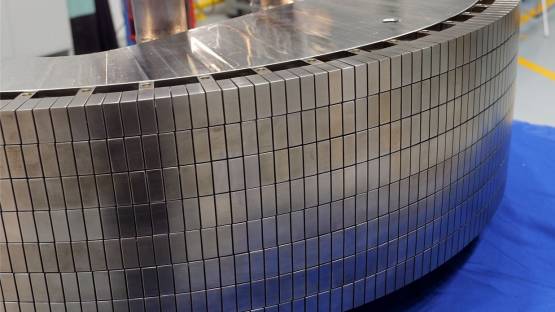

On 21 December 2021, in a facility nine miles south of Oxford’s city centre, the Joint European Torus (JET) fusion device fired up. Using powerful magnets to confine and fuse hydrogen, the tokamak reactor produced a record-shattering 59-megajoule fusion energy pulse over a period of five seconds. The almost forty-year-old JET was able to make the historic breakthrough, thanks in part to a retrofit that replaced its carbon inner walls with metals — a change with important implications for the future of fusion energy development.

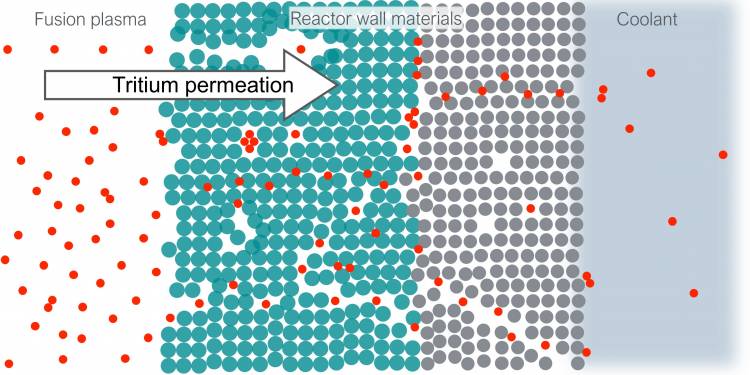

A new IAEA coordinated research project is helping better understand this change and investigate the materials used in future fusion reactors. Gathering international experts from 15 countries, the IAEA and its partners are using a neutron source to recreate the conditions faced by a fusion reactor’s inner wall and determine how hydrogen permeates the metallic components within it. The project’s results could hold important answers to questions regarding the cost, efficiency and waste produced from large fusion experiments and reactors, such as ITER and DEMO as well as future fusion power plants.

“One of the most challenging aspects of a fusion reaction is dealing with the damage caused by released neutrons,” said Kalle Heinola, an IAEA Atomic Physicist coordinating the project. “Performing materials research utilizing neutrons typically requires an expensive neutron source and involves special requirements for radiation safety. Therefore, physicists and engineers have traditionally experimented with materials by bombarding them with ions or through computer simulations. However, these alternatives have drawbacks or limitations and may not accurately represent the damage neutrons can cause. Our project addresses that.”

The neutron irradiation will give researchers unparalleled insight on how neutrons create intrinsic defects in materials and help them to uncover the driving mechanisms behind hydrogen permeation in different metals.