In-field inspections form the core of the IAEA’s nuclear verification activities, and equipping inspectors with the appropriate tools is key to effective nuclear safeguards. Over a hundred types of equipment are used by IAEA inspectors to verify the form, isotopic composition and quantity of nuclear material.

Inspectors typically select three to five hand-held pieces of equipment for each inspection. “There is no such thing as a typical inspection,” said Alain Lebrun, Head of the IAEA Non Destructive Assay Section that provides monitoring tools for inspector use. “Equipment is selected by inspectors on a case-by-case basis.”

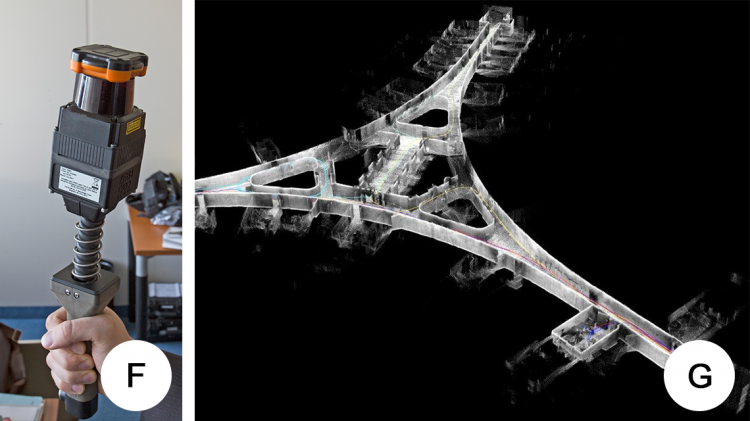

Technicians prepare, calibrate and pack up the devices, which are carried by inspectors or — if they are too bulky — are shipped to their destination ahead of time. The most widely used hand-held equipment is non-destructive analysis instruments. These detect the presence of nuclear material (uranium, plutonium and thorium) and its specific characteristics. Specialized instruments assess physical characteristics — temperature, weight, volume, thickness and light emission/absorption — of nuclear materials.

“The equipment needs to be technologically advanced, versatile, rugged, and userfriendly,” Lebrun said. Equipment experts continuously review and optimize the instruments, keeping up with technological innovation and simplifying user interfaces.

Sometimes commercially available equipment can be used with minimal customization, while in other cases equipment is specifically developed for and/ or by the IAEA. “Some of these tools cost more than a sports car,” Lebrun said.

Radiation detectors