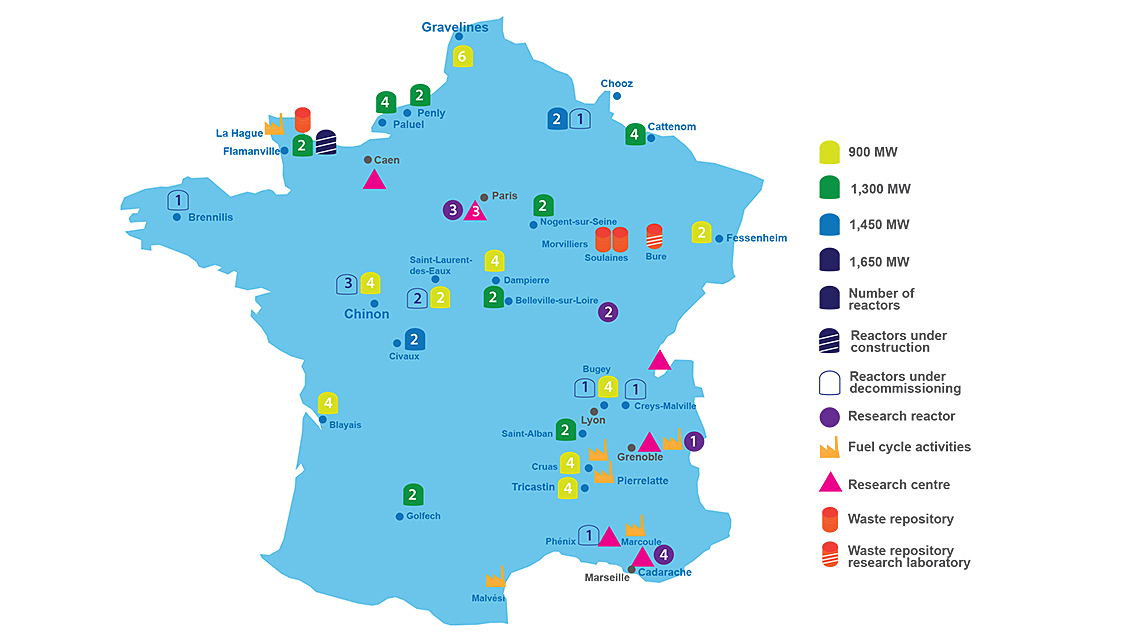

With 58 nuclear power reactors producing nearly 72% of France’s electricity in 2018, France is one of the countries with the highest share of nuclear power in its energy production. Along with this energy, however, France’s nuclear fleet is also responsible for producing a significant amount of spent fuel and radioactive waste.

The strength of France’s national spent fuel policy, in addition to tight legislation and a strong regulatory body, can be attributed to the standardization of its nuclear fleet and the policy of recycling its spent fuel, French experts have said. This leads to an efficient and secure supply and a reduced radioactive waste burden.

In France, all operating units are pressurized water reactors of just three standard types, all designed by Framatome: three-loop 900 MWe (34 reactors), four-loop 1300 MWe (20 reactors) and four-loop 1450 MWe (4 reactors). French nuclear power reactors, therefore, have the highest degree of standardization among countries with large nuclear fleets. This also translates into a standardized approach when dealing with the back end of the nuclear fuel cycle, which involves spent fuel and waste management, decommissioning, and environmental remediation.

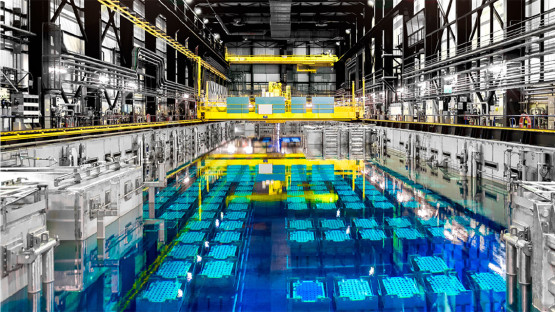

To manage the nearly 1150 tonnes of spent fuel it produces every year, France, like several other countries, decided early on to close its national nuclear fuel cycle by recycling or reprocessing spent fuel. In doing so, the French nuclear industry can recover uranium and plutonium from the used fuel for reuse, thereby also reducing the volume of high-level waste.

The nuclear fuel recycling process involves converting spent plutonium, formed in nuclear power reactors as a by-product of burning uranium fuel, and uranium into a “mixed oxide” (MOX) that can be reused in nuclear power plants to produce more electricity.

“The recycling of spent fuel is a major element of the strategy of the French nuclear sector, which has more than 30 years of industrial experience,” says Denis Lépée, Senior Vice President and Head of the Nuclear Fuel Division at EDF, the French electric utility company that operates the country’s nuclear power plants.

“This makes it possible to limit the volume of materials and to minimize waste, while conditioning it in a safe way. This strategy, which is an important pillar of France’s overall nuclear electricity production, makes a significant contribution to the country’s energy independence.”

The recycling of spent fuel is a major element of the strategy of the French nuclear sector, which has more than 30 years of industrial experience.